RUBBER

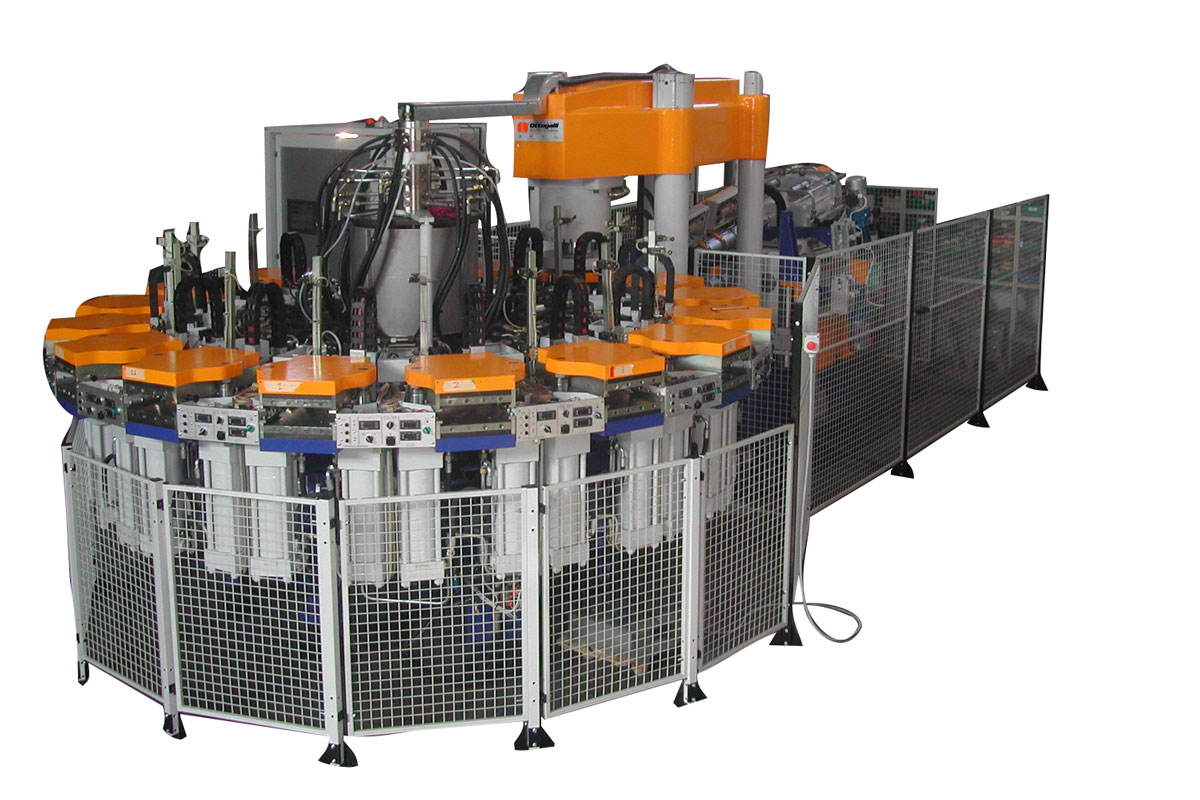

Configuration: Rotary press

Finished product: Direct Injection on Upper

Material: Rubber

Multi-station static linear machine for the injection of rubber and cross-linked thermoplastic materials for the production of:

-Simple soles, slippers, insoles, inserts and fillers single color

-Technical items (ex. floats) single color

Technical details ITF2 920 TS

| Number of Stations | n. 16 |

| Number of Injectors | n. 1 (1+1 optional) |

| L/D ratio | L/D 21 |

| Injection volume | cc 1150 |

| Theoretical Max Injection Flow Rate | cm3/sec 320 / 360 |

| Hydraulic Motor Displacement | cc 800 |

| Max Screw Rotation Speed | rpm 180 |

| Max torque at 120 rpm | daNm 100 |

| Standard Mold Size | mm 250x400 |

| Max Heating Power | Kw 4 |

| Force Closing mold holder | Guaranteed by Mechanical Hydraulic System |

| Automatic Mold Holder Opening | Standard |

| Blowing Air Into the Molds | Blank |

| Mold Heating | |

| Maximum Height of The Molds | mm 160 |

| Press Closing Force | kN 1600 |

| Energy Saving Plumbing | Standard (Brushless Optional) |

| Maximum Service Pressure | kg/cm2 140 |

| Proportional Flow Valves | Standard |

| Proportional Speed Valves | Standard |

| Electric unit with Plc and Video Touch screen | |

| Total Installed Power | kW 75 (Brushless kW 70) |

| Average Steady-State Consumption | kW 50 (Brushless kW 40) |