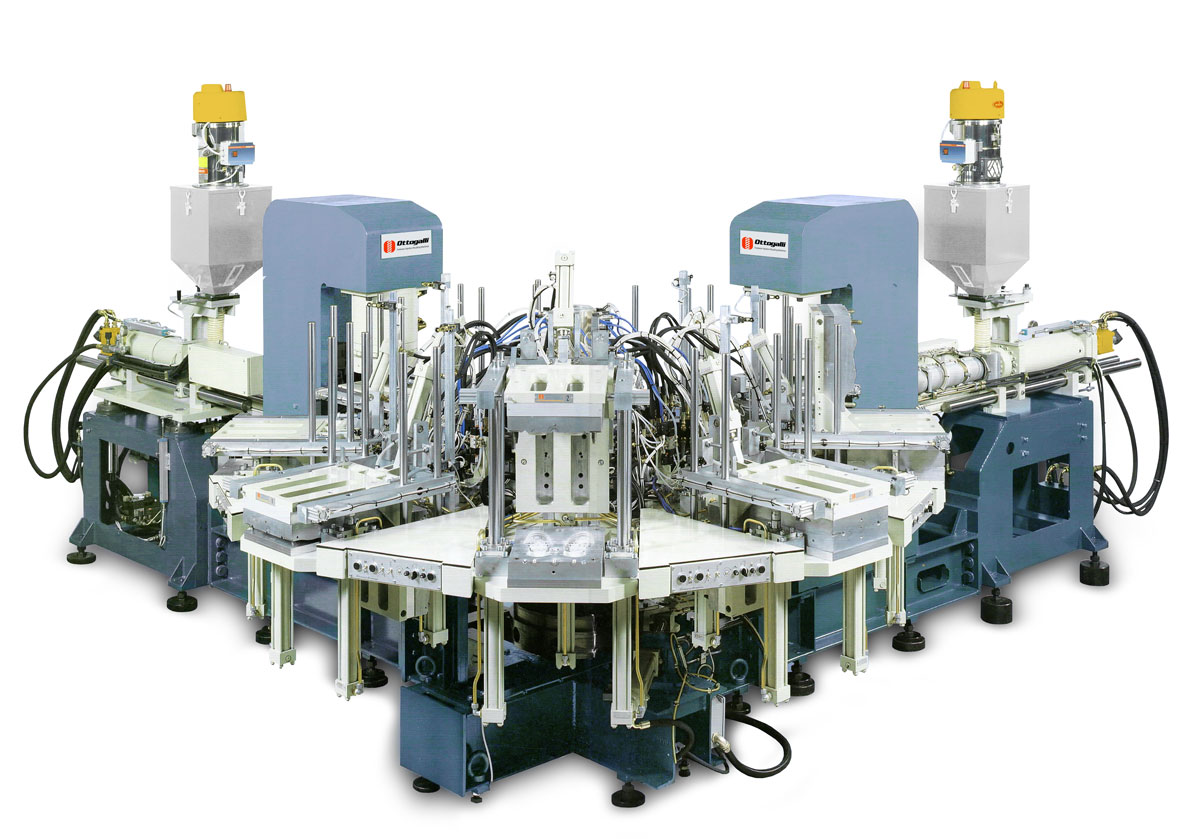

EPS2

Configuration: Rotary press

Finished product: soles

Material: Thermoplastics PVC TR TPU

8- or 10- working station rotary machine for injection of soles made of compact or expanded thermoplastic material single and two-color pvc, expanded pvc, tr and microtech.

Press with a reinforced structure that provides a clamping power of 1,200 KN.

Technical details

| Number of stations | n. 6/8/10 |

| Number of injectors | n. 2 |

| Diameter | ø65 o (ø75 mm on request) |

| L/D ratio | L/D 21 o 20 |

| Injection volume | cc 1150 / 1350 |

| Theoretical max injection flow rate | cm3/sec 320 / 360 |

| Hydraulic Motor Displacement | cc 500 |

| Max screw rotation speed | rpm 180 |

| Max torque at 120 rpm | daNm 100 / 110 |

| Standard mold size | mm 300x400 |

| Max heating power | Kw 7+7 |

| Force Closing mold holder | Guaranteed by mechanical hydraulic system |

| Automatic mold holder opening | standard |

| Blowing air into the molds | standard |

| Mold cooling | standard |

| Maximum height of the molds | mm 160 |

| Press closing force | kN 1200+kN1200 |

| Energy saving hydraulic system | Standard (Brushless Optional) |

| Maximum service pressure | kg/cm2 140 |

| Proportional flow valves | standard |

| Proportional speed valves | standard |

| Electric unit with Plc and Video Touch screen | standard |

| Total installed power | kW 60 (Brushless kW 60) |

| Average steady-state consumption | kW 35 (Brushless kW 27) |